- Heddels

- Posts

- Sept 17 - Waxed Cotton History I&R

Sept 17 - Waxed Cotton History I&R

Together with

The History of Waxed Cotton – Mariners, Steve McQueen, and Farmers

We look at how waxed cotton came into being, what it is, where it's been used, and present a few solid options for your wardrobe.

John Patterson

You might notice it on an old Barbour jacket. Perhaps a piece of luggage, or even on an ancient cargo tarp. The uses of waxed cotton textiles are nearly endless, and manufacturers have used it for centuries to provide a lightweight and durable fabric that’s both waterproof and breathable. The dawn of the fabric, however, is rooted in Renaissance seafaring.

Waxed Cotton’s Inception

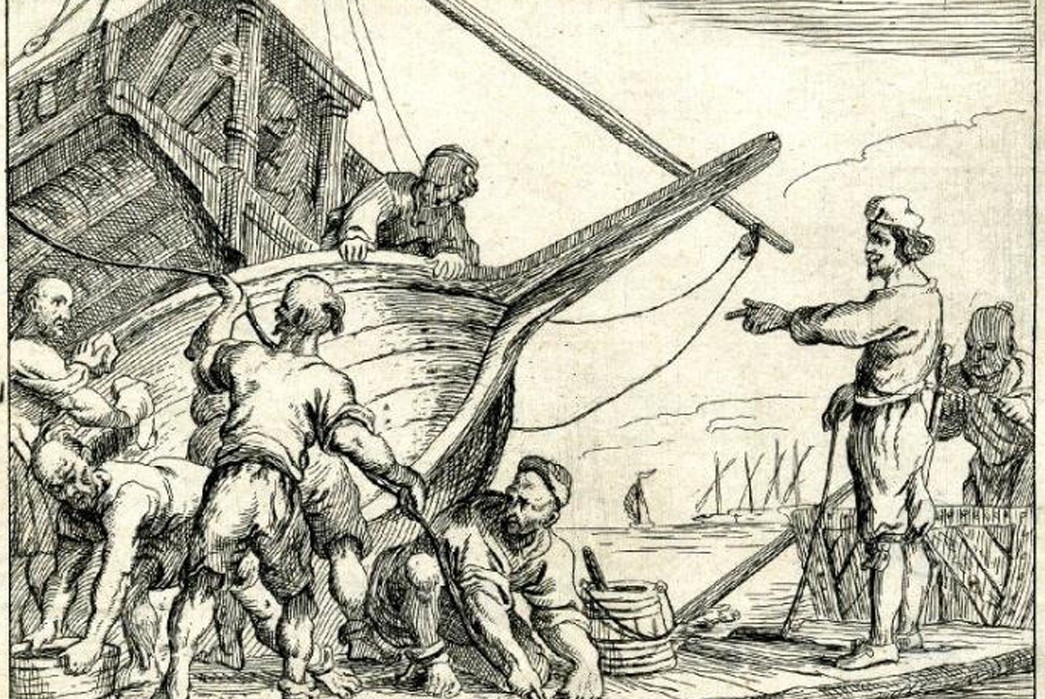

Woodcut of seventeenth-century sailors. Image via Pics Vault.

Around the mid-fifteenth century, mariners noticed their sails became more effective in catching the wind when they were wet with seawater, but the water’s extra weight still slowed them down. Slathering up their sails with fish oils and grease made the sails just as useful as when they were wet but they still remained light as the fish oil and grease worked as waterproofing. The extra greased material left over from the sails just happened to make for great protective capes for the sailors themselves, and some of the first waxed (or greased) clothing was born.

A few centuries later, linseed oil was used on heavy-duty flax sails. With the growing demand for lighter and more efficient sails, construction evolved from heavy flax to cotton, with finer yarns woven into a stronger, two-fold construction. By the mid-1850s, waxed cotton sails were a big hit with the Royal Navy and other fast sailing boats of the time known as “Clippers”. Not only did waxed cotton boost sail production, but it also made a utilitarian fabric that was viable for outerwear and hats.

Waxed Cotton as We Know It

One of the original racing jackets from the Six Days Trial. Image via Barbour.

However, waxed cotton was yet to be perfected. Linseed oil presented a variety of issues, from turning yellow (a hallmark that would influence the yellow coloring of early fishermen’s clothing) to cracking in cold conditions, hindering its weather-resistant properties.

In the 1920s, the now-legendary cotton finishing company, British Millerain, helped to solve this problem by pioneering the development of paraffin-based waxed cotton with two other British textile manufacturers. Instead of simply treating the finished cotton with a wax coating, the new process impregnated the cotton with paraffin wax prior to weaving it tightly. Parrafin-impregnated cotton offered improved weather resistance and breathability, without the deteriorating properties of linseed oil. These developments helped formalize the production of waxed cotton as we know it today.

Filson catalog snippets from 1914 (left) and 1922 (right), via Filson

While forms of waxed cotton had already hit stateside in the late 19th century, the first brand to invest in the new paraffin-waxed cotton was Filson. While the exact dates are unknown, it is generally accepted that Filson obtained rolls of British Millerain paraffin-treated khaki drill from international traders in the 1920s. This fabric was listed as ‘waterproofed khaki’, but Filson went on to develop its own proprietary waxed (oiled) fabric, tin cloth.

Since the 1920s we’ve seen other usages in waxed cotton beyond the shipping industry. J. Barbour & Sons (Barbour) was one of the early adopters of waxed cotton in the Outdoors and Motorcycling Industries. In fact, the British racing team sported Barbour’s motorcycle suits for the duration of the line (1936-1977), also extending itself to the American team in the 1964 International Six Days Trial, which King of Cool himself, Steve McQueen, raced for.

The British Army’s use of waxed cotton for its waster-resistant clothing in WWII led to the material’s escalation in the 1940s and 1950s.

A waxed version of the British Special Forces Denison Smock used in WWII. Images via Wikimedia and Pinterest.

/ In Partnership with Iron & Resin /

If California rugged adventure label Iron & Resin had to be summed up in a single product, it would be their Scout Jacket. This rugged piece of outerwear has been in the I&R collection since 2014 and it represents everything we’ve come to love about their work.

The Scout is a waxed canvas jacket takes the blueprint of the Type III trucker and adds in a little extra kick at every level to make for a more capable and resilient piece. The original denim has been swapped for a 12oz. British Millerain waxed canvas that’s water resistant, breathable, and ages to show patina like crazy. Pair that with stainless steel shank buttons and an additional Talon zipper, and the Scout is essentially fail-proof. The interior has been beefed up with a 9oz. Klamath flannel blanket lining and the collar and hand pockets have soft corduroy trim.

This is the three-season jacket is the perfect companion for the trail to your bike to the bar for a lifetime of wear, as it’s also backed by Iron & Resin’s Repair or Replace Guarantee. So get out there in your Scout, there’s things to see.

Available in Oil Tan, Oak Brown, and Charcoal at for $349 at Iron & Resin.

Waxed Cotton Today

Since the early 20th century, the production of waxed cotton has had more competition in lightweight water-resistant fabrics such as nylon, PVC, polyester, and their various water-proofing treatments such as GORE-TEX. However, the material has never really fallen out of favor. Farmers and countrymen in their thousands still wear waxed cotton jackets by labels such as Barbour, Belstaff, and Filson, and the fabric has seen a surge in popularity in the last 15 years.

Barbour, Belstaff, and Filson remain the three labels synonymous with waxed cotton, but contemporary heritage brands such as Bradley Mountain, Loyal Stricklin, Freenote Cloth, Rogue Territory, and Dehen 1920 all regularly use waxed cotton to create rugged clothing and accessories. The types of cotton waxing materials include paraffin (the most common), oils, and Martexin – a heavy-duty fabric wax made from a blend of beeswax, plant-based waxes, and oils.

New vs. heavily worn Barbour Bedale Jackets, via Wax & Tartans.

One could say that when it comes to heritage fashion, waxed cotton is preferred over say, GORE-TEX nylon, because of its historical context and ability to gain a crinkly patina unique to its wearer. While today’s wax treatments are streets ahead of the linseed oil-saturated cotton of the 18th century, all wax treatments will dry out over time, creating shimmering channels of wax that are beginning to dry out and brighten. This brings us to our next topic.

How to Maintain Waxed Cotton

Waxed cotton is a hardy fabric that lasts a very long time. To maintain the waxed coating, it’s best to minimize laundering and stick to spot washing if required. Otter Wax makes a range of really decent range of products to help maintain your waxed goods, including a spot-washing soap.

You may like the faded look of your waxed cotton goods, but if you want maximum water resistance you’ll want to explore re-waxing. You’ll know it’s time to re-wax your waxed goods when they’re dirty past the point of being spot-cleaned or treated with a dash of wax in a pale/dry area, or the wax has melted noticeably, evaporated, pooled into spotty patches, or isn’t deflecting rain and wind the way you want it to. You’ll see less dark, oily, and waxy hues on the item, and more of the pale interior cotton coming through.

For our full guide on re-waxing, check out How To Re-wax Waxed Cotton Materials.

Waxed Goods You’ll Want to Use Forever

Like leather, waxed canvas can be found on a plethora of goods from Barbours to ball caps. Not all waxed goods are made equally, though – so here are our picks of some of the highest-quality waxed canvas clothing and accessories on the market.

Rogue Territory Waxed Supply Jacket

Dehen 1920 Crissman Overshirt Waxed Cotton

Bradley Mountain Bags

Freenote Cloth Waxed Riders Jacket

American Trench Waxed Trench Coat

3sixteen Waxed Canvas Ball Caps

Devium Overdrive Waxed Trucker Jacket

What did you think of today's newsletter? |