- Heddels

- Posts

- July 14 - 4 Fabric Printing Techniques – Discharge, Resist, Silkscreen, and More

July 14 - 4 Fabric Printing Techniques – Discharge, Resist, Silkscreen, and More

4 Fabric Printing Techniques – Discharge, Resist, Silkscreen, and More

A primer on 4 fabric printing techniques, from ancient resist dyeing methods to the modern-day inkjet tech deployed by conglomerates.

Albert Muzquiz

At Heddels, we’re all about weaves. We love our twills, our jacquard, and sashiko, but we don’t often talk about the printed patterns on our clothes. There are several important fabric-printing techniques, and for some reason, we’ve never fully discussed them before; therefore, we’re addressing this right now.

The way people have printed on fabric over the years is wide and varied, but we’re breaking down the four most common techniques you’re liable to encounter.

Woodblock

Image via Cleobella

Woodblock printing involves using a relief-carved wooden block to transfer pigment onto a piece of material. This technique can be combined with other printing/dyeing techniques to create super intricate designs.

Woodblock printing has functions far beyond sprucing up textiles. Since antiquity, this technique has been used for all manner of artwork and writing. The earliest examples of woodblock printing are seen on silks from the Han dynasty in China, which dates them back to before 220 C.E. It would be hundreds of years before Europeans figured out this same technology.

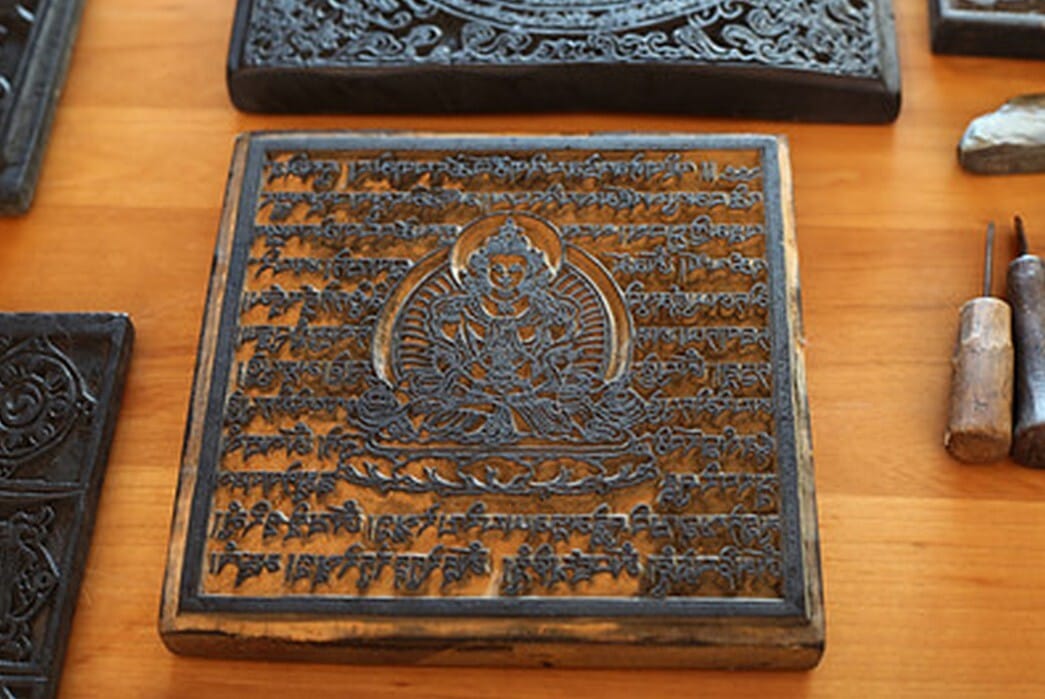

An actual woodblock. Image via Latse Library.

Woodblocks vary widely in intricacy, but in many ways, they are the most logical printing technique. You cut your pattern in relief, chipping away the wood for areas you wish to remain undyed, and make sure your design is reversed so that it isn’t backward once it lands on the fabric. All one needs for woodblock printing is wood, carving tools, ink, and fabric. Printing like this made disseminating ideas much easier and created a novel yet logical way to put art on stuff.

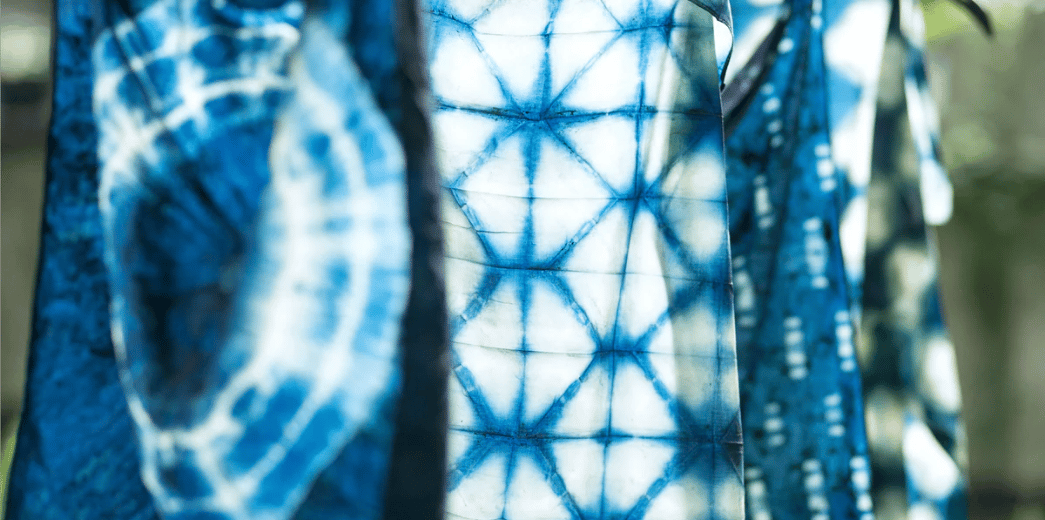

Resist

Image via FabricSight

A flip side of woodblock printing is resist-dyeing. This technique involves treating parts of a fabric so that they resist being dyed when pigment is applied. This is most famously exhibited via tie-dye, whereby the brute force of tightly tying the fabric stops dye from reaching certain areas.

Dubble Works Lot.35001 S/S T-Shirt Tie Dye Border, available for $76 from HINOYA.

To achieve more intricate designs, resist dyeing involves the application of wax, mud, chemicals, or another substance in the form of a pattern. This substance then resists being dyed when dye is applied. After being dipped in dye, the treated areas will remain undyed, revealing the undyed pattern. The earliest example of this technique was found on linen mummy wrappings in Egypt. These wrappings had been coated in mud, then had the mud scratched away, whereupon they were dipped in a dye of blood and ashes. The remaining mud was washed away with hot water, revealing the design.

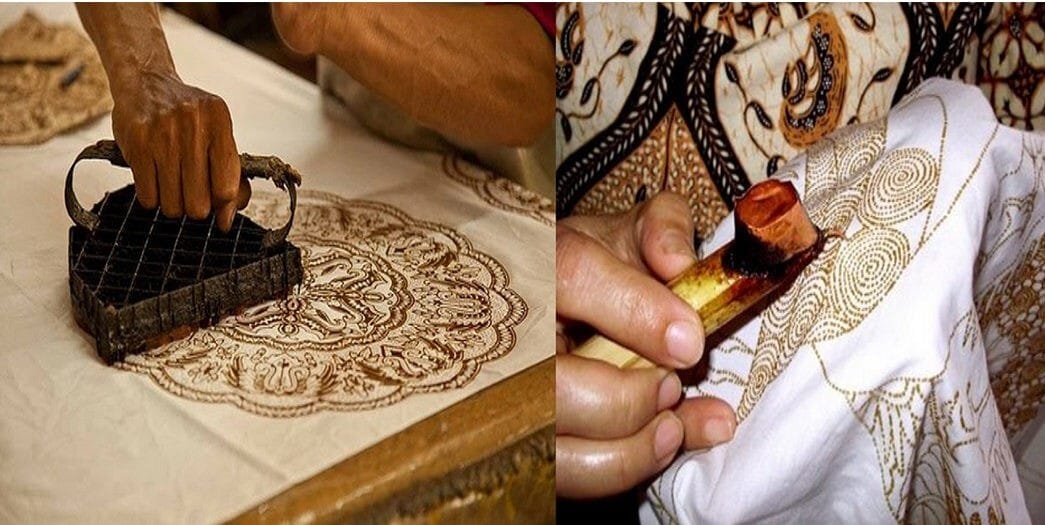

Batik, an Indonesian wax-resist dye technique. Image via Real Margaria Batik.

Resist-dyeing is essentially an abstraction of the woodblock system. Oftentimes, the mud, wax, or paste is transferred onto the fabric with a device like a woodblock, into which the design is carved in relief. Batik, one of the most esteemed resist-dye techniques, comes from Indonesia. Incredibly intricate designs are carved and then used to transfer wax to the fabric. Once the fabric has been dipped in dye and the wax is washed away, you have gorgeous patterns.

11.11 Indigo-Dyed Batik Print shirts, available for $447 from DeeCee Style.

We flew to Pakistan back in 2018 and explored the world of Ajrak, an ancient textile that blends resist dyeing and wood block use. Prior to each dyeing process, a resist paste, traditionally made from a mixture of lime and arabic gum, is applied using a woodblock to treat certain areas of the fabric. The history of Ajrak probably deserves its own article, but you can see a snippet of our trip to Pakistan in the above video (the bandana is long sold out, though!)

Discharge

Image via HINOYA.

Discharge printing is a little different from the previous techniques. With discharge printing, bleach or discharge ink is applied to a fully dyed fabric using a stencil. This removes the pre-existing dye, creating a pattern or print.

You’ll recognize discharge printing from the legions of graphic tees you see every day. This process also keeps your tee super-soft because no actual ink is added. Certain discharge inks can actually replace the pre-existing dye with another color. In some ways, this technique is similar to resist dyeing, in that you need to make a stencil with which to focus your dyes. Discharge printing is commonly seen in our niche through the creation of wabash stripes and the production of patterned bandanas.

Iron Heart 12oz Wabash Painter’s Pants – Indigo, available for $324 from Iron Heart.

Momotaro Cotton Bandana Navy, discharge printed in Japan and available for $35 from Redcast Heritage.

Screen Printing (Silkscreen)

Andy Warhol printing with a silkscreen via Halcyon Gallery.

Screen printing is now the most ubiquitous of fabric printing techniques, and like the woodblock, its origins are Chinese. Screen printing was used as far back as 960 C.E. and did not make it to Europe for quite some time, because of the silk it required. Nowadays, the mesh used in screen printing is usually nylon or a synthetic polymer, but it must be under a fair amount of tension to function correctly.

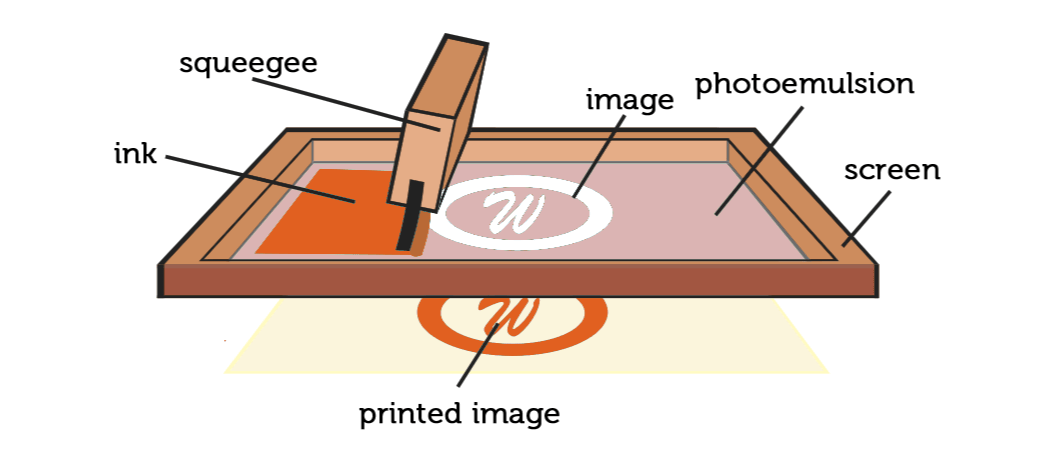

Screen printing diagram vis Sunrise Metal. Photo emulsion is a light-sensitive substance essential to the screen printing process. It’s applied to a screen, and when exposed to light, the emulsion hardens in specific areas while remaining soft in others. The hardened sections create a stencil, enabling ink to pass through only the intended parts of the design during printing.

A stencil is made that blocks off all parts of the fabric that will not be dyed. After the screen has been adequately prepared and the artisan is sure that no dye will seep in anywhere unintended, a dye is scooped across the stencil with a squeegee, which transfers the design to whatever surface you so desire.

Screenprinting may be common, but it isn’t exactly simple. It requires patience and skill, especially when working with different colors.

Iron Heart Printed Heavyweight Loopwheel T-Shirts, available for $115 from Iron Heart.

Digital Inkjet Printing

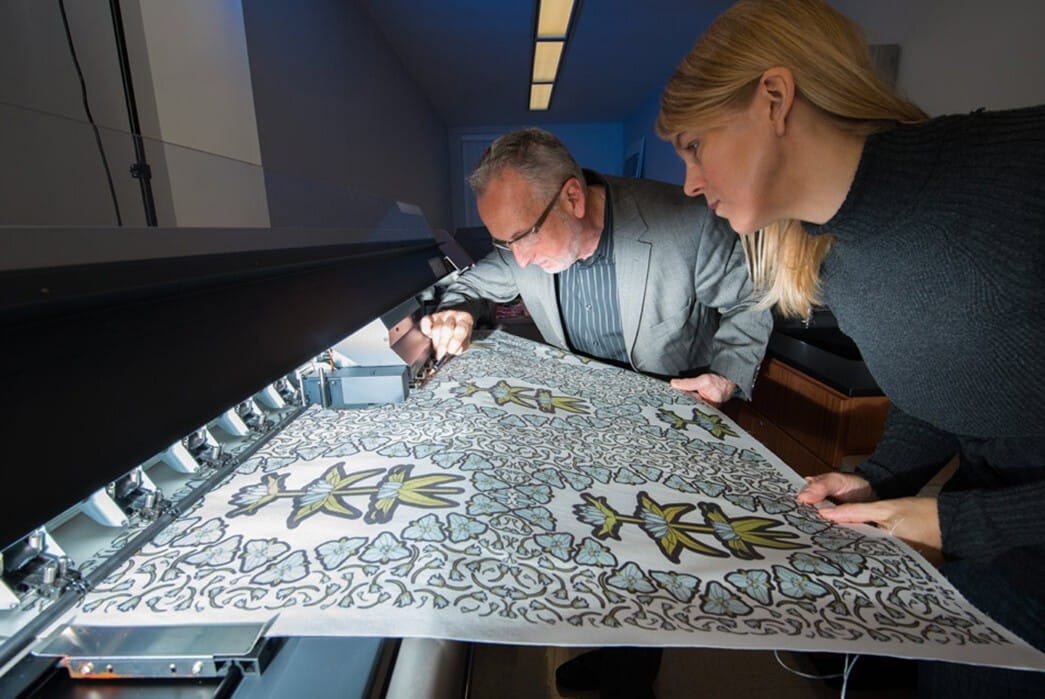

Digital Textile Printing. Image via University of Nebraska.

A relatively new technology in the context of this article, digital textile printing has only been possible since the late 1980s. Although, dye-sublimation technology was created in the early 90s and allowed for designs to be printed directly onto fabric (usually nylon) without necessitating a sheet of transfer paper.

Sublimation ink, which is the industry standard, is much-liked because it bonds directly with the fibers of the textile (or as it is often called: the media) and doesn’t simply rest on the surface.

The vast majority of patterned textiles on the market today are printed digitally, as it is often the cheapest, fastest, and most exacting way to put ink on cloth. It’s a fast-growing industry, but certainly lacks some of the attention to detail and humanity that makes the other techniques so special.

Like this? Read these:

What did you think of today's newsletter? |