- Heddels

- Posts

- Aug 5 - Selvedge Denim Mills to Know I&R

Aug 5 - Selvedge Denim Mills to Know I&R

Together with

The 12 Selvedge Denim Mills to Know – From Cone to Kuroki

Ever wondered where selvedge is made? We rundown the 12 need-to-know selvedge denim mills around the world, from Japan to North Carolina.

James Smith & Albert Muzquiz

Denimheads fetishize the means of production more than just about any other community. Not only do we want to know what brand made the jeans, we want to know where the cotton came from, and who milled it into glorious selvedge denim.

These questions, however, aren’t easily answered by the average consumer who rarely sees their jeans prior to a store shelf or postage box. In this article, we’d like to highlight some of the key denim mills in the world producing selvedge fabric to give you a glimpse of what goes on where.

Japan

Kuroki Mills

Kuroki Mills was founded in 1950 by Tamotsu Kuroki, but it wasn’t until 1960 that they would begin to produce denim. And it’s just as well they did, because they remain one of the most revered denim mills in the game to this day.

Originally, Kuroki vat-dyed their denim (somewhat heretical in the raw selvedge denim community), but by 1965, they’d begun rope-dyeing. This gave their denim a more authentic look and allowed it to develop fades that mimicked and even rivaled those of the original American blue jeans makers.

By 1970, Kuroki was producing denim exclusively, and in 1988, they moved to the factory pictured above. It is now one of the only denim mills with integrated dyeing, weaving, and finishing facilities, meaning it can produce just about any heritage fabric.

Shockoe Atelier Slim Kojima Jean in 17 oz. Kuroki Mills Big Slub Denim, available for $285 from Shockoe Atelier.

Kuroki now supplies selvedge denim and other quality fabrics to some heavy hitters in the industry including 3sixteen (check their tour of Kuroki here), Freenote Cloth, Shockoe Atelier, and Hiut denim.

Loyal Stricklin TPR Fit Jean, 15 oz. Kuroki Slub Selvedge, available for $260 from Loyal Stricklin.

/ In Partnership with Iron & Resin /

Iron & Resin knows a thing or two about toweling off with terry. They’re based in the surf mecca of Ventura, California and their new terry collection features tops and bottoms to help you lounge in comfort and style.

Their Terry Shirt, Polo, and Shorts are all available now and starting at $49 at Iron & Resin.

-

Want to see your name here? Send us an email at [email protected]

Collect Mills

People say that an organization is only as good as its weakest link, and there are certainly no weak links in that conglomeration known as Japan Blue Group from Kojima. Everything began with Collect, the actual mill and fabric provider, which was founded in 1992.

Momotaro 2105SP-5 15.7oz Going To Battle Type II Jacket, available for $335 from Redcast Heritage.

For 14 years, meticulously weaving selvedge denim on antique looms was enough, but by 2006 they decided to apply their denim to their own designs and founded the now-famous Momotaro brand. Named after a mythical peach boy from Japanese folklore, Momotaro even gave their jeans a signature pink-line selvedge to do their namesake justice.

Momotaro 0405-40 14.7 oz. ‘Legacy Blue’ Selvedge Denim High Tapered Jeans, available for $254 from Redcast Heritage.

In 2010 Japan Blue Jeans was founded, selling similarly high-quality jeans at a lower price point. The brand first focussed on this offering, but has expanded to produce shirting, t-shirts, and even sweatshirts. Collect uses Momotaro for refined, heritage-inspired selvedge denim jeans, whilst Japan Blue Jeans pushes the envelope with contemporary designs and washes.

Japan Blue 14.8oz US Cotton Straight Selvedge Jeans J401 Mid Wash, available for $265 from Iron Shop Provisions.

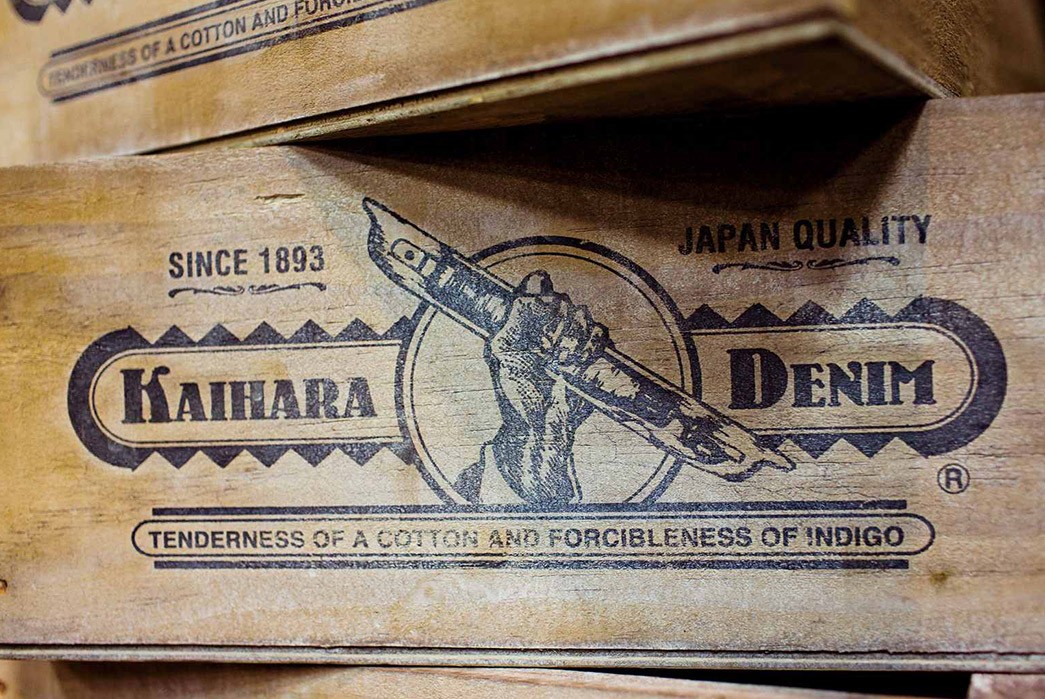

Kaihara Mills

Kaihara Mills. Image via JCrew

Kaihara Mills was established in 1951, but its origins lie in its founder’s first-ever indigo weaving endeavor in 1893. Sukejiro Kaihara was an indigo expert, something conveyed in nearly all his company’s endeavors.

For years, Kaihara Mills has been a ceaseless innovator, patenting and developing new machines to improve the dyeing and weaving processes. In 1970, they independently developed a rope-dying machine that they insist was the first in Japan (although the jury’s out on this one—Kuroki says they started doing this five years earlier), and Kaihara never stopped improving their equipment.

Levi’s Vintage Clothing 1953 Type II Jacket Kaihara Rigid, available for $405 from Cultizm.

In 1977, Kaihara set a world record for the most rope-dying ever done in a single month of production. This is no surprise considering they weave most of LVC‘s Japanese denim and supply to global giants like Uniqlo, Edwin, and Nudie. Other brands that make goods from Kaihara denim include Freenote Cloth and Tellason.

Tellason Gustave Kaihara Mills Indigo Selvedge, available for $291 from Cultizm.

Nihon Menpu Mills

Via Paul Trynka and Loomstate

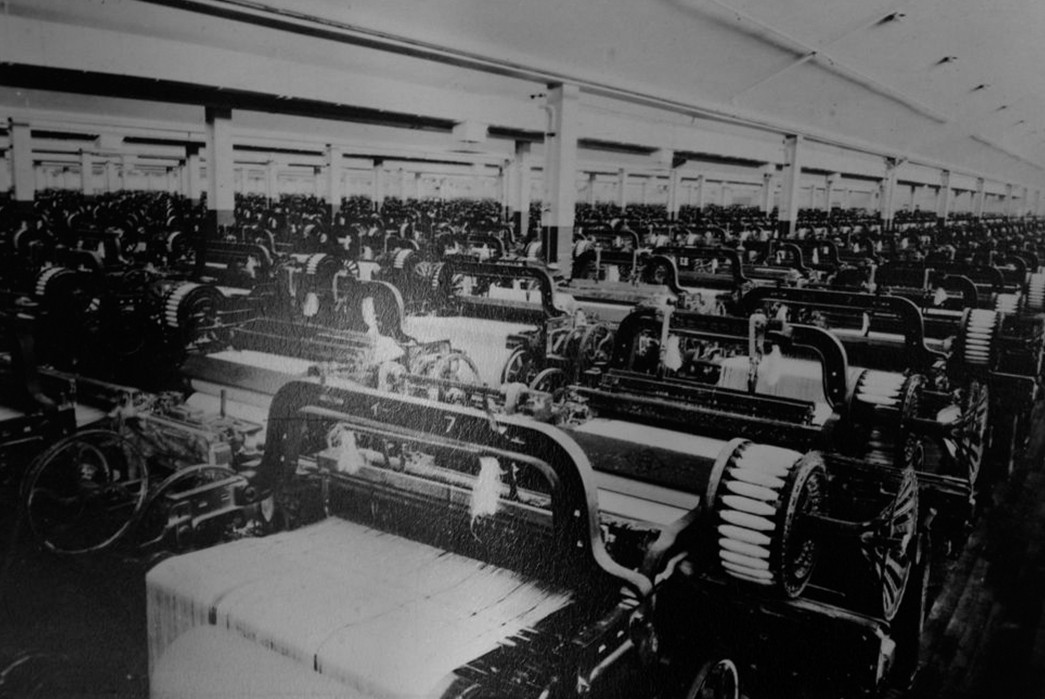

Nihon Menpu is an old mill established in 1917 but the company didn’t fully commit itself to denim production until 1985. This happened at a time when the global standards of denim production were beginning to decline and mass production on high-speed looms was the most common and profitable way to do things.

But Nihon Menpu slowed things down by using old-fashioned looms to make a higher-quality selvedge denim.

Work Trouser – 15oz Nihon Menpu Hemp/Cotton Selvedge, available for $349 from Loyal Stricklin.

Their yarn-by-yarn philosophy has certainly paid dividends, they now provide denim to big denim brands like Rogue Territory and Edwin, as well as being appreciated and utilized by a range of smaller makers in the scene.

Skinner American Goods Standard Fit Jeans 22 oz. Extra Heavyweight Nihon Menpu Mills Selvedge, available $275 from Skinner American Goods.

Nisshinbo Mills

Nisshinbo Mills has existed in one way or another since 1907, when it was established as the Nisshin Cotton Spinning Company.

They produce all kinds of textiles, from denim to shirting cloth, anti-odor fabrics, and synthetics. But despite the success of some higher-tech fabrics, one Nisshinbo’s specialty remains their ring-spun denim. Largely phased out in the 1970s, ring-spun denim is a more labor-intensive process, which gives the surface of denim a more irregular and vintage look.

Nisshinbo has supplied denim to brands like Taylor Stitch and Left Field, but has fallen out of favor in recent years and Nisshinbo denim is rarely utilized by the biggest and best denim makers.

Kurabo Mills

Kurabo‘s esteemed history begins with its founding in 1888 in Kurashiki, Okayama. But it wasn’t until 1970 that they entered the denim business. They made a big splash with their KD-8 Kurabo denim, which was marketed as the first denim ever made in Japan. (The histories are awful fuzzy about this, aren’t they?)

But even considering the contested legacy, it’s absolutely certain that Kurabo was one of the most crucial trailblazers in Japan’s denim history because it was their denim that was used by Big John, one of the first Japanese jeans companies.

Ginew Thunderbird Jacket in Kurabo Denim, available for $270 from Franklin & Poe.

Toyoshima Mills

Toyoshima was founded in 1841 and now functions as a fabric wholesaler. They also produce some wild novelty fabrics like bamboo and hibiscus blends. Their innovative denim has historically been used by Freenote Cloth.

Everywhere Else

As you may have noticed, Japan takes center stage when it comes to weaving selvedge denim these days. That said, there are/were a handful of other important mills in other parts of the world.

Cone Mills

Cone Mills was the last of a dying breed— a selvedge denim mill in the United States. Founded by Moses and Caesar Cone in 1891 in Greensboro, North Carolina, the company got its big break with the so-called “Golden Handshake” in 1915, made with Levi Strauss Co. This informal handshake deal made Cone Mills the exclusive denim-provider for Levi’s, and the deal lasted until Levi’s moved production overseas. Cone Mills products could be identified by the red line in their selvedge edge and the characteristic inconsistencies in the fabric, which came from a slight bounce in the wooden factory floors as the Draper X3 looms did their thing.

On December 31, 2017, Cone Mills closed the doors on its last remaining selvedge denim plant, White Oak — a move that abruptly ended American selvedge denim as we knew it. Selvedge denim is no longer woven by Cone Mills in the USA. Makers scrambled to buy the last yards of the most iconic blue denim ever created, so luckily, goods made from deadstock Cone Mills White Oak selvedge denim still be purchased, often on a limited-run basis.

Mister Freedom California Lot. 54 Reissue NOS Cone Mills White Oak Selvedge, available for $400 from Franklin & Poe.

Proximity Manufacturing Company, White Oak Legacy Foundation

The White Oak Legacy Foundation, Inc. (WOLF) exists to preserve the history of denim weaving in Greenboro, North Carolina. The closure of Cone Mills White Oak Plant left many without jobs and threatened the legacy forged by Cone Mills, the epicentre of American selvedge denim production.

To further their preservation efforts, WOLF established Proximity Manufacturing Company in 2021. Operations are based at the former White Oak Plant, first opened in 1905 in NE Greensboro. Aiming to keep the White Oak flame alive, WOLF and Proximity Manufacturing employ ex-Cone employees who have the technical knowledge to run the remaining Draper X3 shuttle looms.

Tellason x Proximity Manufacturing Co. Straight Leg Jeans, available for $395 from Tellason.

Keeping things as traditional as possible, Proximity Manufacturing Co. produces selvedge denim using cotton yarns sourced from Mount Vernon Mills, a longstanding American textile giant. A visit to the WOLF website will show you this is just the tip of the iceberg, and that Proximity Manufacturing is extremely serious about keeping traditional American selvedge alive.

Vidalia Mills

After the closure of the Cone Mills White Oak Plant shook the selvedge denim scene to its core, Louisiana’s Vidalia Mills came through to keep American selvedge alive. Vidalia was established in 2014, taking over an old Fruit of the Loom premises to create a farm-to-yarn mill, working with American farmers to source certified sustainable cotton

Skinner American Goods Standard Fit 14 oz. Vidalia Selvedge Denim Jeans, available for $225 from Skinner American Goods.

When White Oak shut down, Vidalia purchased 46 of the original Draper X3 looms to add to their fleet of shuttle and power looms.

While the aforementioned Proximity Manufacturing is arguably a micro-mill, offering made-to-order runs of traditional selvedge, Vidalia is a big operation producing a lot of selvedge denim. They have supplied denim to brands like Left Field NYC, Raleigh Denim, Imogene + Willie, and Skinner American Goods.

Wies Made Selvedge Denim Ball Cap 14 oz. Vidalia Mills, available for $65 from Wies Made.

Candiani Mills

On the floor of the Candiani mill.

Candiani got its start in 1938 outside of Milano, Italy. Candiani has been family-run since its inception, and after over 75 years in the business has declared itself the greenest denim mill in the industry.

They have won a number of awards for their commitment to sustainability, and with their two factories, they are the largest denim producer in Europe.

Benzak Denim Developers BDJ-T2 Jacket in two types of Candiani Selvedge Denim, available for $232 from Benzak.

Berto Mills

Also hailing from Italy is selvedge denim mill Berto. Founded by two brothers in Bovolenta in 1887, Berto supplies regular non-selvedge denim, of course, but does things the old-fashioned way too. Their line called “Blue Selvedge” relies on 1950s “Picanol style mechanical scaffoldings” to give their denim that authentic feel. Specially trained operators and repair people keep the machines and this antiquated form of production alive.

What did you think of today's newsletter? |