- Heddels

- Posts

- Aug 4 - Understanding The Difference Between Japanese and American Selvedge Denim

Aug 4 - Understanding The Difference Between Japanese and American Selvedge Denim

Understanding The Difference Between Japanese and American Selvedge Denim

A look at the differences between Japanese and American selvedge denim from the perspective of their histories and manufacturing methods.

James Smith, Nick Coe

Japan and the United States have worked diligently to establish themselves as the two premier manufacturers of raw selvedge denim in the world. As an antiquated process, the milling and production of raw selvedge denim has all but disappeared in many areas of the world. Despite this, the Japanese and Americans have continued to produce the highest-quality, most coveted denim in the world.

Sadly, the closure of both the Cone Mills White Oak plant in 2017 and Vidalia Mills in 2025, American selvedge is now a very small industry. Proximity Manufacturing Co. is keeping the flame alive, but it is not producing anywhere near the yardage that White Oak or Vidalia was, at the writing. That said, American selvedge isn’t dead, and there are still yards of deadstock White Oak selvedge being sewn into denim garments every year, in addition to limited edition releases made of Proximity Manufacturing fabrics.

But the question still remains in the minds of potential buyers – which is better? Japanese or American selvedge? Whether or not there is a clearly superior denim could be debated endlessly and ultimately boils down to personal preference. However, we are going to dive into the details and look at some of the typical differences between Japanese and American indigo raw selvedge denim. Does one have a clear advantage over the other? Let’s find out.

Texture

American Selvedge

Modern American selvedge denim woven by Proxmity Manufacturing Co., a project of the White Oak Legacy Foundation (WOLF) that aims to produce selvedge denim in Greensboro, NC, using the same looms from the now-closed Cone Mills White Oak Plant.

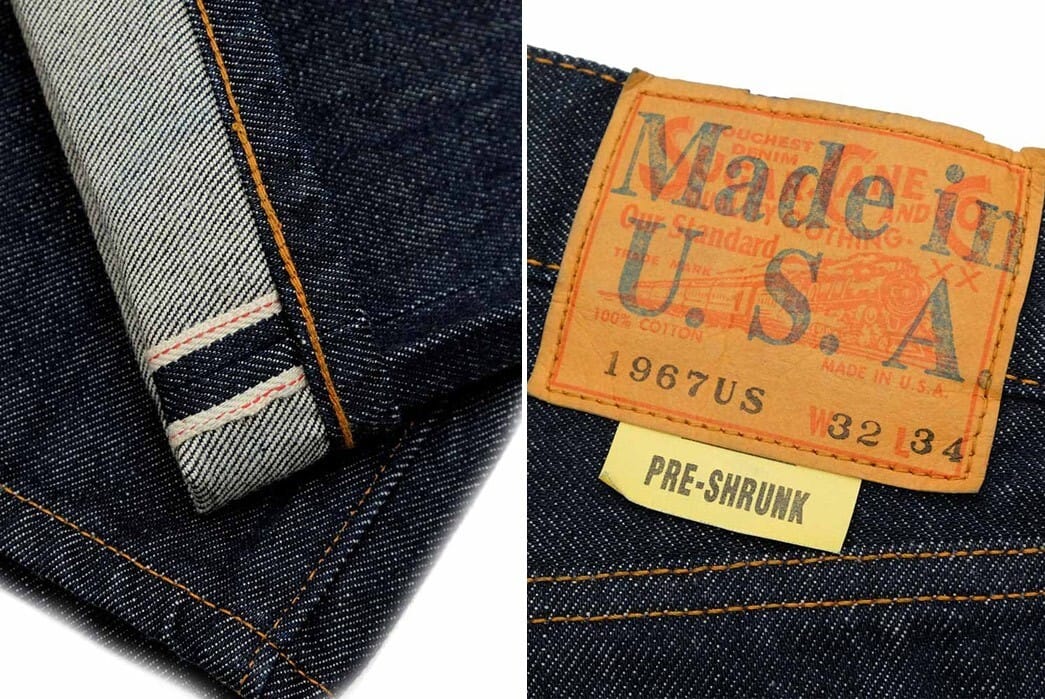

Simply put, American selvedge is known for having a flatter, more uniform texture, while Japanese denim is known for more nuanced fabrics that have higher levels of slub, nep, and/or other textural details. American denim usually has a denser weave, giving rise to a mild sheen when in its raw state.

The golden age of American raw selvedge denim was centred on supplying the American workforce — miners, railroad workers, soldiers, the list goes on. Mills weren’t scrambling to chase trends or produce something totally unique; they were simply making as much of it as possible to outfit blue-collar workers who were building the USA.

Sugar Cane Jeans made from Deadstock Cone Mills White Oak Selvedge Denim, via HINOYA.

American denim was woven by Amoskeag Mills (RIP), Cone Mills White Oak Plant, and Mount Vernon Mills, the latter of which is the largest manufacturer of non-selvedge denim in the USA today. White Oak produced denim for the big three — Levi’s, Lee, and Wrangler — and its selvedge became the gold standard of American selvedge denim. It famously used Draper x3 shuttle looms that produce a dense weave with subtle blips of slubby weave caused by the slubbier ring-spun yarns of the time, and the infamously bouncy wooden floors of the White Oak facility.

American selvedge denim is still available today, either through deadstock rolls of selvedge woven at the late White Oak plant, or through products that use denim from Proximity Manufacturing Co., a small operation that uses the Draper X3 looms from White Oak to produce modern American selvedge.

Seven Titans Straight Fit Jeans, Proximity Manufacturing Selvedge, available for $525 from Seven Titans.

Japanese Selvedge

Close-up of some slubby denim by Japanese denim label, Samurai. Image via Redcast Heritage

While the Japanese can, and often do, weave denim to mirror American selvedge from specific decades in the 20th century, they also weave a wide array of proprietary fabrics and have a denim culture entirely of their own. The Japanese took the concept of American denim and made it their own by both worshipping it and building upon it.

Most Japanese mills use vintage Toyoda shuttle looms to weave their selvedge denim. By modern standards, these looms are slow and unpredictable, but the Japanese lean into these imperfections, often introducing metrics like slub yarns or machine alterations to increase the amount of ‘loom chatter‘ that will ultimately create a unique and nuanced fabric.

ONI Denim’s “Crushed Concrete” selvedge denim, via Blue Beach Denim.

Brands like ONI Denim, Samurai Jeans, and Pure Blue Japan are just a few Japanese denim brands known for their slubby, neppy fabrics, and it’s fabrics like these that convert a lot of folk to Japanese denim. That said, Japanese mills do weave reproductions of American denim – see brands like Full Count, Jelado, Resolute, and Denime for reference.

Resolute 14 oz. sanforized denim via Trunk Clothiers. Notice how the denim is more uniform, not hairy, and has a very slight sheen – woven in Japan to replicate Cone Mills Selvedge.

Fades

Generally speaking, Japanese raw denim is known to produce higher contrast fades while American raw denim is known for more subdued fades with more overall dye loss. It’s worth considering that most of the denim woven by Cone Mills was sanforized, while Japan produces more unsanforized denim, which is less mechanically processed and yields more unpredictable, high contrast fades. This is not a hard and fast rule, though, and the below image is just a general example from our fade archives.

LVC (USA) vs. Samurai Jeans (JP) fades. Notice how the LVC fades on the right are more subdued, while the Samurai fades are more stark and striking.

Key Facts:

Both American and Japanese selvedge denim are often woven on shuttle looms, including vintage Draper X3 looms (USA) and Toyoda shuttle looms (Japan). These looms weave selvedge denim slowly when compared to modern power looms.

American selvedge denim is typically smoother and more uniform in texture than Japanese denim, which is often slubby and/or neppy. It is also more densely woven, giving rise to a slight sheen.

Unlike Japanese denim, American denim often does not have the same slubiness and texture that many denim enthusiasts look for. The denim does have a unique texture, but it is not as pronounced as the texture tends to be with Japanese denim

American selvedge denim is now barely produced in the USA after the closure of key mills.

Japan has a number of mills that produce selvedge denim, leading to a variety of fabrics with different characteristics.

Japanese denim generally produces higher contrast fading with defined creases, while American denim produces more subtle fades.

Like this? Read these:

What did you think of today's newsletter? |